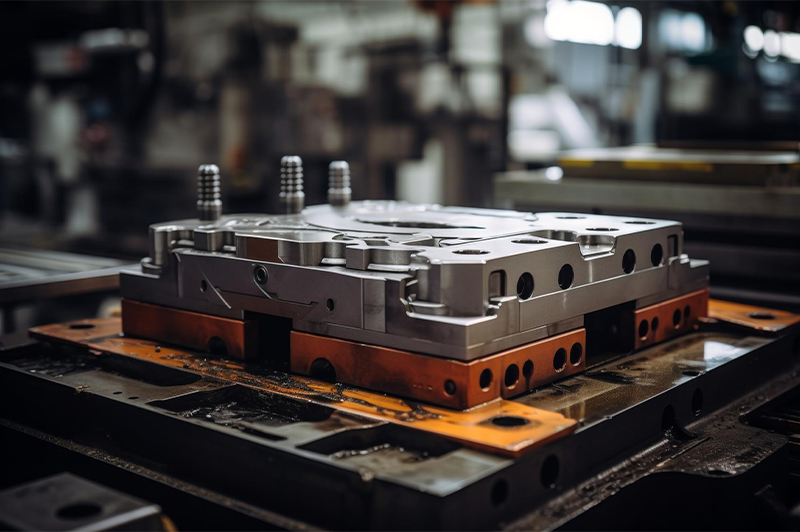

Stamping Die

Stamping tooling is not merely a metal forming tool; it is a critical foundation that determines quality consistency, process controllability, and long-term production efficiency in mass manufacturing. The way tooling is developed—and how thoroughly it is integrated into production planning—has a direct impact on production stability, yield performance, and overall manufacturing cost control.

For Kun Feng Metal Industrial Co., Ltd., tooling is not treated as an isolated item. It is an integral part of the manufacturing process, closely linked with product requirements, material selection, stamping process planning, quality control, and mass production conditions. The objective of tooling development is not only to achieve successful forming, but to ensure stable, repeatable performance under actual long-term production environments.

Integrating Tooling Development into Process Planning

In practical projects, tooling development does not begin after product design is finalized. Instead, it is incorporated into overall process planning from the early stages of the project. During tooling development, the following factors are evaluated and integrated in parallel:

- Material characteristics and actual forming behavior

- Stamping sequence and process logic

- Production takt time and efficiency requirements

- Interface conditions with downstream processes such as welding, surface treatment, and assembly

By developing tooling and process planning simultaneously, the risk of repeated adjustments during mass production is significantly reduced, allowing tooling to be production-ready at the time of completion.

Tooling Design Principles Oriented Toward Mass Production

Successful tooling design is not defined solely by whether a part can be formed, but by whether stable performance can be maintained under continuous production conditions. Accordingly, tooling design focuses on:

- Dimensional repeatability during long production runs

- Process tolerance control under mass production conditions

- Tool life and long-term reliability

- Minimizing dependency on manual adjustments during production

This approach ensures tooling is not just usable, but suitable for long-term mass production—supporting stable yields, shorter adjustment time, and reduced overall manufacturing cost.

Common Stamping Tooling Types & Applications

Depending on part structure, volume requirements, and process complexity, different tooling concepts are applied in practice. Tooling selection is not based on type alone, but on choosing the solution most suitable for stable, long-term production under actual manufacturing conditions.

Single Operation Die

Single operation dies are typically used for relatively simple parts or applications requiring flexible process sequencing. By separating blanking, bending, or forming operations, higher flexibility in process adjustment and quality control can be maintained. This tooling type is also commonly applied in low-volume but stable mass production, balancing manufacturing efficiency and cost control.

Compound Die

Compound dies perform multiple blanking or forming operations within a single station. They are suitable for parts requiring high positional accuracy, coaxiality, or dimensional consistency. By integrating multiple operations, cumulative process variation is reduced, making compound dies well suited for mass production requiring consistent quality.

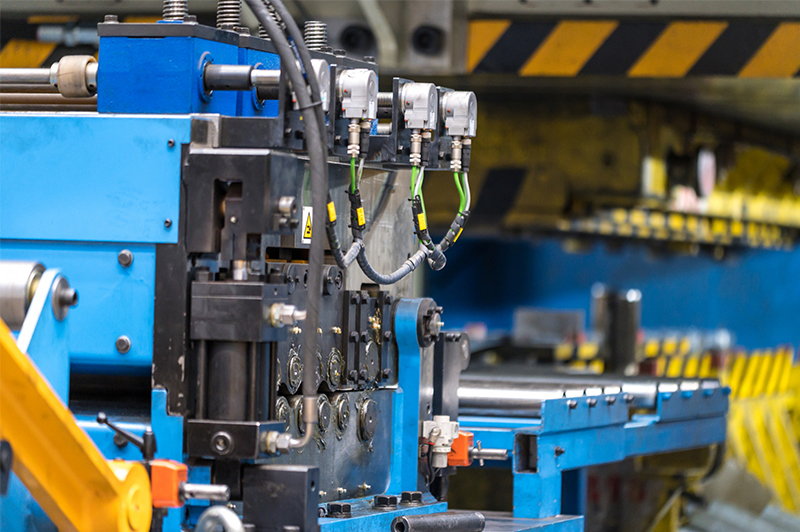

Progressive Die

Progressive dies integrate multiple operations into a single tooling system, with material fed continuously through sequential stations. This tooling type is primarily used for high-volume mass production, offering stable process conditions, high efficiency, and reduced unit cost over long production runs.

Transfer Die

Transfer dies move individual workpieces between stations to complete multiple forming steps. They are suitable for more complex parts, parts with multiple forming stages, or applications not suitable for continuous strip feeding. Transfer dies offer a balance between forming controllability and production efficiency in mass production environments.

Drawing / Deep Drawing Die

Drawing dies are applied to cup-shaped, box-shaped, or deep-formed components. Tooling design emphasizes material flow control and forming stability to prevent wrinkling, cracking, or excessive springback, ensuring consistent appearance and dimensional quality under mass production conditions.

Forming Die

Forming dies are used for parts with specific bend angles, contours, or three-dimensional geometries. Process control focuses on forming accuracy and springback management. These dies may be used independently or in combination with other tooling types as key forming steps within mass production processes.

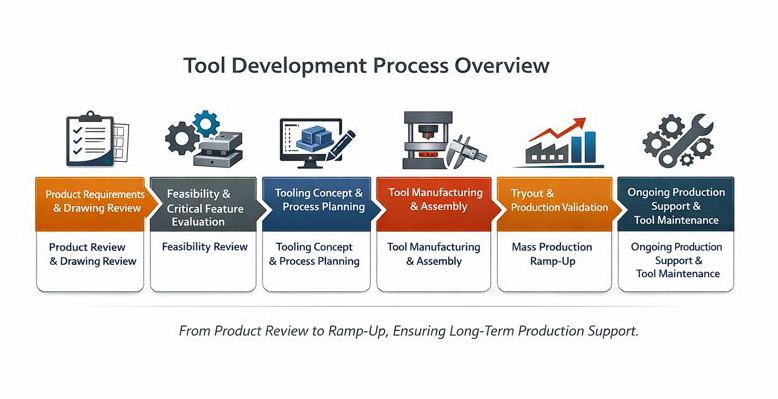

Tool Development Process Overview

Tool development begins with a review of product requirements and drawings. At the early stage of each project, technical discussions are conducted with customers to clarify product functions, critical dimensions, and key forming features, ensuring feasibility under actual mass production conditions and identifying potential risks in advance. These early evaluations directly influence tooling structure, process planning, and overall cost allocation.

Through a structured development process, tooling performance is validated for stability and repeatability before mass production. By establishing early alignment on critical dimensions and functional features, the need for subsequent tooling revisions can be reduced, along with the risk of cost increases and schedule impacts caused by repeated design changes.

Tool Manufacturing, Tryout & Mass Production Validation

Tool tryout is not conducted solely to confirm one-time forming results, but to verify feasibility under mass production conditions. Through tryout and necessary adjustments, dimensional consistency, forming quality, and process repeatability during continuous production are confirmed prior to production release. Tooling and process records are managed within the quality management framework to ensure traceability for future production and process changes.

Ongoing Tool Maintenance & Production Support

During mass production, tooling is treated as a critical production asset rather than a one-time investment. Through monitoring of tool condition, wear evaluation, and necessary maintenance activities, tooling performance is maintained to support consistent quality and production efficiency over long-term manufacturing cycles.

Tooling Capability as Part of Integrated Manufacturing

Tooling development is not a standalone service, but an essential component of integrated stamping manufacturing capability. The close integration of tooling, stamping, production, and quality systems enables KF Stamping to participate in process planning from early project stages—helping customers reduce mass production risks, improve production stability, and establish manufacturing solutions suitable for long-term operation.