Precision Stamping

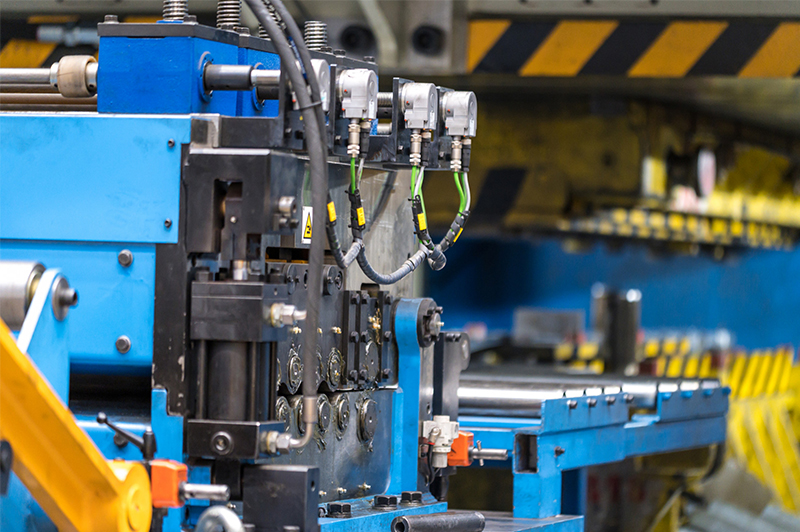

Precision stamping is not defined by a single machine or process.

In the metal stamping industry, it refers to a manufacturing capability that consistently delivers tight tolerances, stable quality, and repeatable results in high-volume production.

Unlike general stamping, which focuses primarily on forming parts to shape, precision stamping emphasizes process control, dimensional stability, and functional reliability over long production runs.

How the Industry Defines Precision Stamping

In practice, precision stamping is recognized through several closely related characteristics.

Dimensional accuracy under mass production.

Precision stamping is measured not by prototype results, but by the ability to maintain tight tolerances consistently in continuous production. Key dimensions must remain stable over time, across tool life, material batches, and production cycles.

Process stability and tooling control.

True precision stamping relies on well-designed tooling, controlled forming conditions, and stable production processes that minimize variation. Without process stability, tight tolerances cannot be sustained.

Edge quality and form consistency.

For functional or assembly-critical components, edge condition and form accuracy are essential. Precision stamping focuses on controlling burrs, deformation, and edge variation to ensure reliable downstream assembly and performance.

Integrated quality control.

Precision stamping does not depend solely on final inspection. Quality control is embedded into the production process through incoming material verification, in-process dimensional checks, and final inspection aligned with customer specifications.

General Stamping vs. Precision Stamping

| Aspect | General Stamping | Precision Stamping |

|---|---|---|

| Primary Focus | Basic part formation | Dimensional stability and repeatability |

| Tolerance Capability | Standard tolerances | Tight and repeatable tolerances |

| Process Consistency | Batch-dependent | Process-controlled for long production runs |

| Edge Condition | May require secondary operations | Controlled directly by the stamping process |

| Quality Control | Primarily final inspection | Integrated in-process control |

| Typical Applications | Non-critical structural parts | Functional and assembly-critical components |

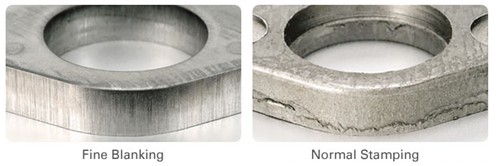

Precision Stamping vs. Fine Blanking

| Aspect | Precision Stamping | Fine Blanking |

|---|---|---|

| Manufacturing Scope | Manufacturing capability | Specialized stamping process |

| Primary Objective | Accuracy and repeatability | Superior edge quality |

| Edge Condition | Controlled, application-dependent | Near-full sheared, exceptionally clean edges |

| Tooling Requirement | High-precision dies | Dedicated fine blanking tooling |

| Secondary Operations | May be required | Often reduced or eliminated |

| Typical Applications | Assembly-critical components | Gears, safety parts, edge-sensitive components |

When to Use Fine Blanking

Fine blanking should be considered when edge quality and dimensional integrity are function-critical, not simply when tighter tolerances are desired.

Fine blanking is the right solution when:

- Edge condition directly affects part function or safety

- Minimal fracture zone is required

- Flatness and edge integrity are critical for assembly

- Secondary machining must be minimized or eliminated

Precision stamping alone may be sufficient when:

- Tolerances can be maintained through controlled processes

- Edge quality is functional but not extreme

- Stable, cost-effective mass production is the priority

Common Misconceptions About Fine Blanking

- Fine blanking is always more precise than precision stamping: Fine blanking excels in edge quality, not necessarily in all dimensional aspects.

- Tight tolerances automatically require fine blanking: The deciding factor is whether edge condition affects part function.

- Fine blanking eliminates all secondary operations: Additional processes may still be required depending on part design.

- Fine blanking is simply a higher-end stamping process: It is a specialized solution, not a universal upgrade.

Precision stamping is defined by control, consistency, and manufacturing capability—not by a single machine or technique. Fine blanking represents one of the highest levels of precision stamping when superior edge quality is function-critical. Beyond process definitions, effective manufacturing depends on making the right technical decisions.

Our role is to help customers:

- Select the most appropriate stamping process based on functional requirements

- Avoid unnecessary process complexity or cost

- Achieve stable, repeatable production over long manufacturing runs

With in-house tooling development and close coordination between engineering and production teams, we focus on manufacturable solutions that perform reliably in real production environments—not just in theory.