Precision Metal Forming

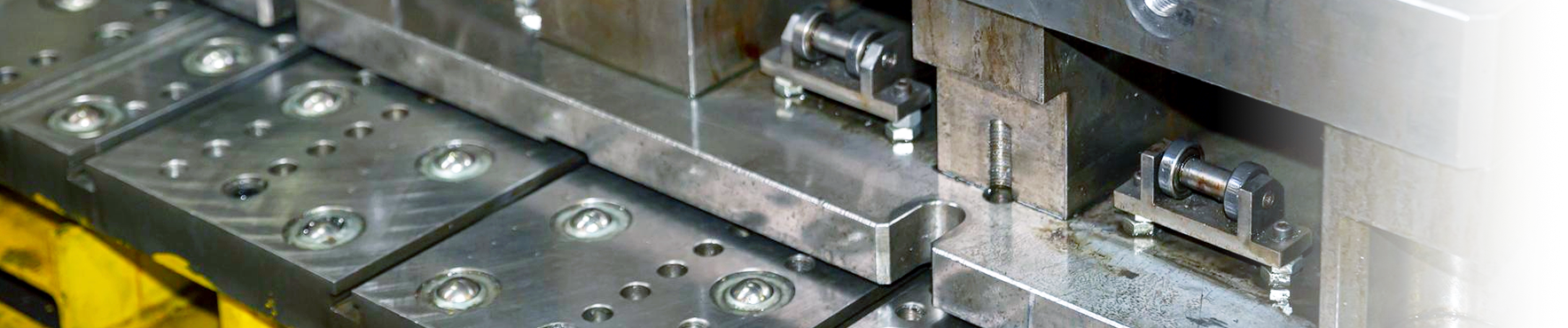

Stamping, also known as pressing, is a manufacturing process that involves placing flat sheet metal—either in blank or coil form—into a stamping press, where a tool and die form the material into its final shape. This process includes a range of sheet metal forming techniques such as punching, blanking, embossing, bending, flanging, and coining. Depending on the complexity of the product, stamping can be executed as a single-stage operation, where each press stroke produces the finished part, or as a multi-stage process that gradually shapes the material through a series of steps.

This method is widely applicable to both metal and non-metal materials, making it a versatile solution for various industries. Its efficiency and repeatability make it especially suitable for mass production, ensuring consistent quality and cost-effectiveness at scale. In addition, stamping supports a flexible production system that allows for adaptation to a wide range of product specifications. With the integration of vertical manufacturing capabilities, the entire process—from material preparation to final output—can be streamlined for greater speed, control, and precision.

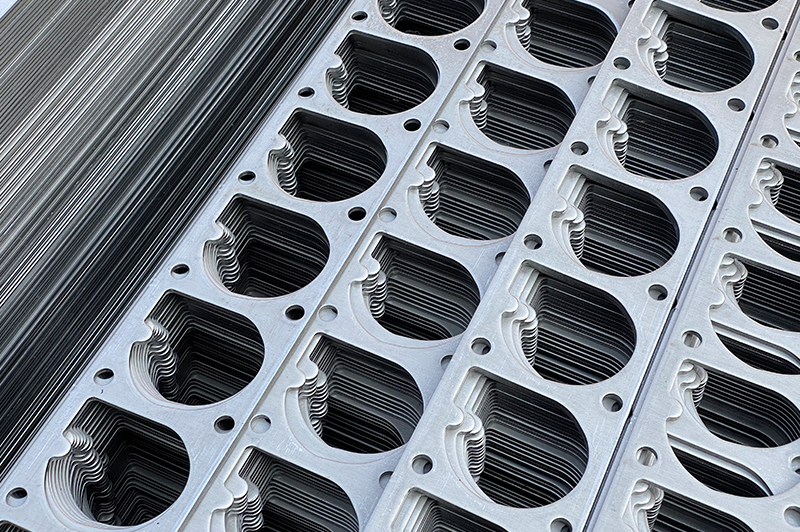

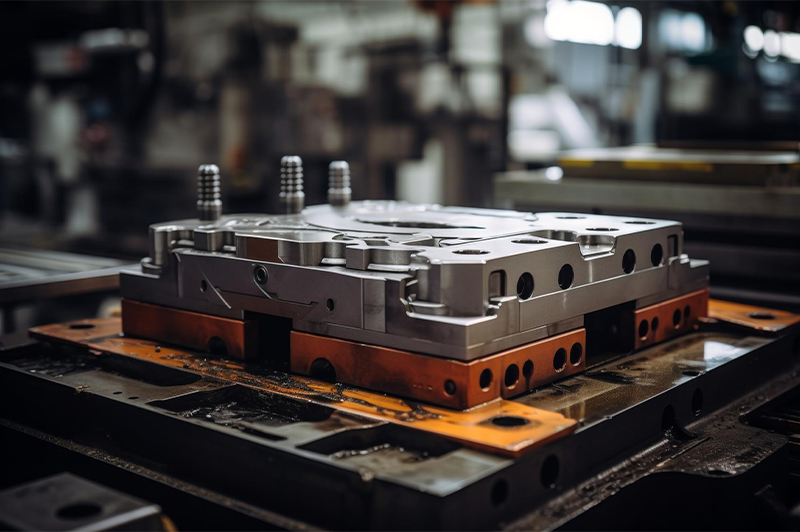

Stamping Die

Generally, sheet metal components are manufactured using various stamping processes, such as punching, bending, cutting, or forming. While simpler parts may be produced in a single press stroke, complex components often require a series of molds or sequential engineering stages to achieve the final shape. Stamping dies are primarily categorized into Single Stage Dies, Compound Dies, and Progressive Dies.

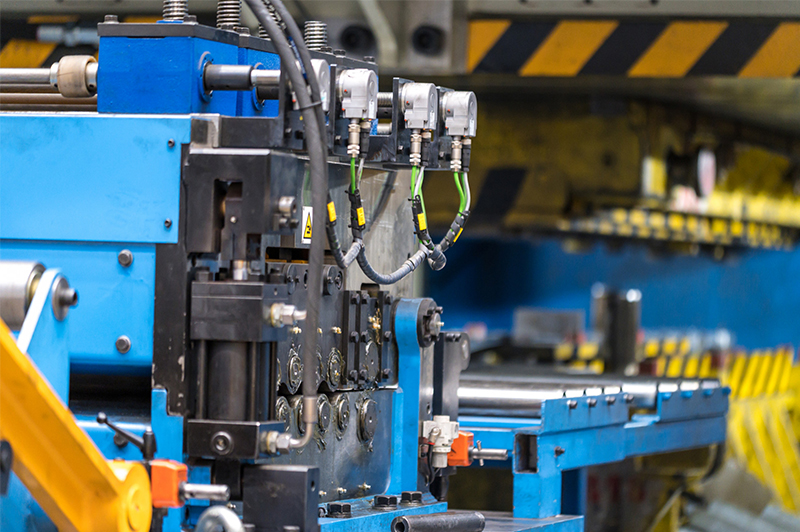

Precision Stamping

Precision stamping is not defined by a single machine or process.

In the metal stamping industry, it refers to a manufacturing capability that consistently delivers tight tolerances, stable quality, and repeatable results in high-volume production.

Unlike general stamping, which focuses primarily on forming parts to shape, precision stamping emphasizes process control, dimensional stability, and functional reliability over long production runs.

Secondary Production Service

One-Stop Manufacturing Support

To simplify supply chain management, Kun Feng provides secondary processing and assembly support through qualified partners.