About

Established Kuen Yung Metal Industrial Co., Ltd.

Expanded production facilities and relocated the factory.

Introduced automated machinery systems.

Completed factory expansion.

Implemented a computerized management system to enhance technical capabilities and operational efficiency.

Achieved ISO 9001 certification. Entered the consumer electronics market (TFT LCD / Plasma TV parts) and invested in 120-ton and 200-ton H-type stamping presses.

Acquired additional stamping machinery to increase capacity.

Launched the "JUESE" brand and entered the high-end audio equipment market.

Certified by RICOH Group for Chemical Substances Management System compliance.

Updated certification to ISO 9001:2008 standards.

Achieved ISO 14001 certification and introduced 2.5D Video Measuring Machines to upgrade quality assurance.

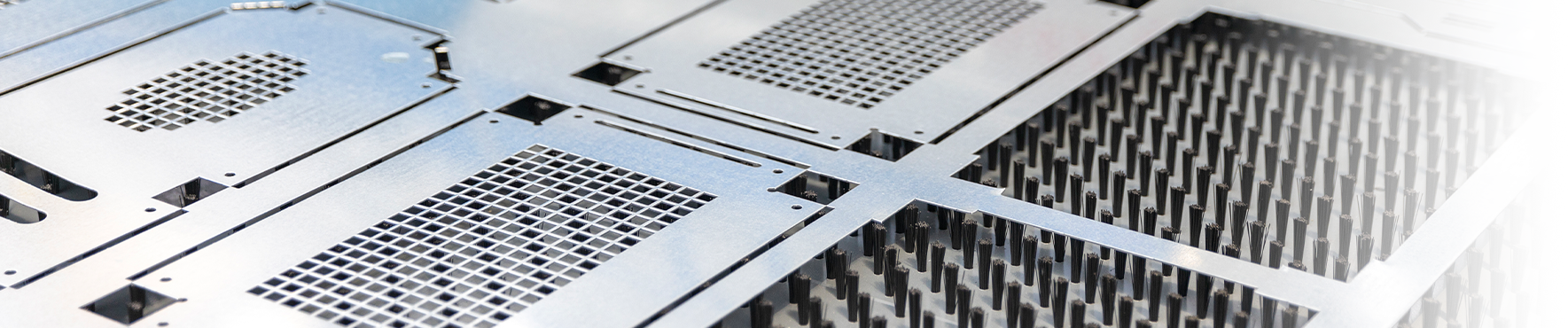

Entered the fine blanking industry.

Invested in a new 400-ton punch press.

Expanded factory by 2,300 m² and upgraded production capabilities.

Acquired heavy-duty material feeders to process thicker metal sheets.

Installed a 1,000-ton stamping press to enhance thick plate processing capabilities (up to 15mm), enabling fine blanking and partial forging operations.

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click Privacy Policy, thank you.