PDCA Cycle

The quality inspection system integrates quality controllers, molding engineers and front-line operators. We strictly control the quality levels from R&D of the product, purchasing, production process to finished product, stage by stage. In addition, the inspection system implements the principle of PDCA management in all circumstances to guarantee a higher level of performance. Furthermore, we not only regularly hold the quality meeting to re-check on process product, but also examine the production of our cooperative factories, which follow up the SOP of the product and comply with RoHS standards for production process.

Plan

R&D and innovation are the most essential assets in the era of knowledge integration. At Kun Feng, we leverage our advanced design capabilities, manufacturing strengths, and deep understanding of market and customer needs to continuously develop cutting-edge technologies and products.

From initial product design to mass production, we provide a total solution for precision sheet metal components — delivering efficiency, quality, and customization every step of the way.

Do

Kun Feng mould team possesses the abilities of design, development and modification. We design and manufacture precision progressive-type moulds or single-type moulds according to customer’s requirements and demands. Moreover, we constantly improve the manufacturing and design techniques in order to provide customers with a wide range of product demand, and, furthermore, challenging the various product ranges and rapidly changing product life cycle.

Tool Making

- Electricity Discharging Machine

- Planetary Surface Grinder

- Turning Machine

- Argon Welder

- Milling Machine

- Forming Grinder

- Cantilever Drilling Machine

- Band Sawing Machine

- CNC Machine

Production

Our production team is well experienced in the abilities of manufacturing, process control and management experience.

In terms of reaching customer's mission accurately, we efficiently manage manpower and facilities from every stage which expecting to full fill customers' quality and delivery demands. In addition, we constantly hold training programs to educate front-line operators that in order to upgrade manufacturing knowledge and techniques, and reaching the goal of professional production, quality assurance and customer satisfaction.

Moreover, the department meetings un-regular hold and closely connect every detailed process of the product that make sure every procedure follow up the standard of process of customer's expectation.

Check

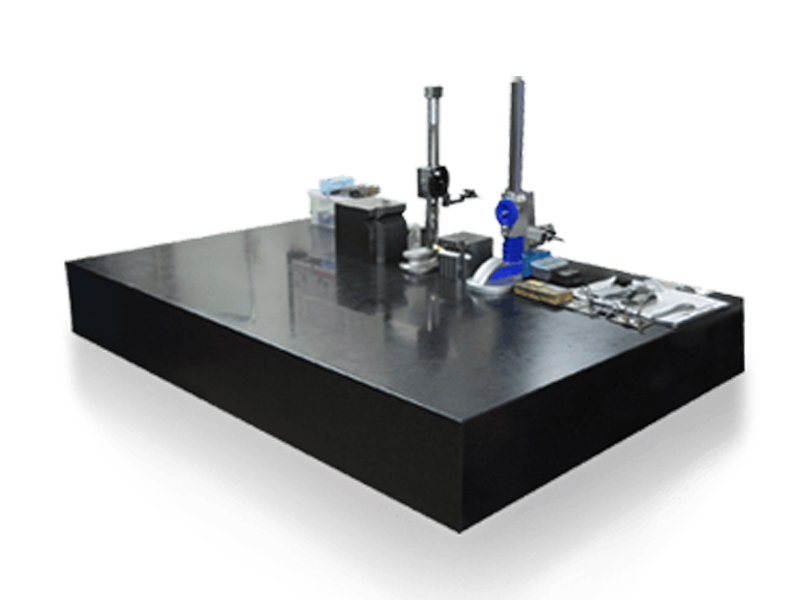

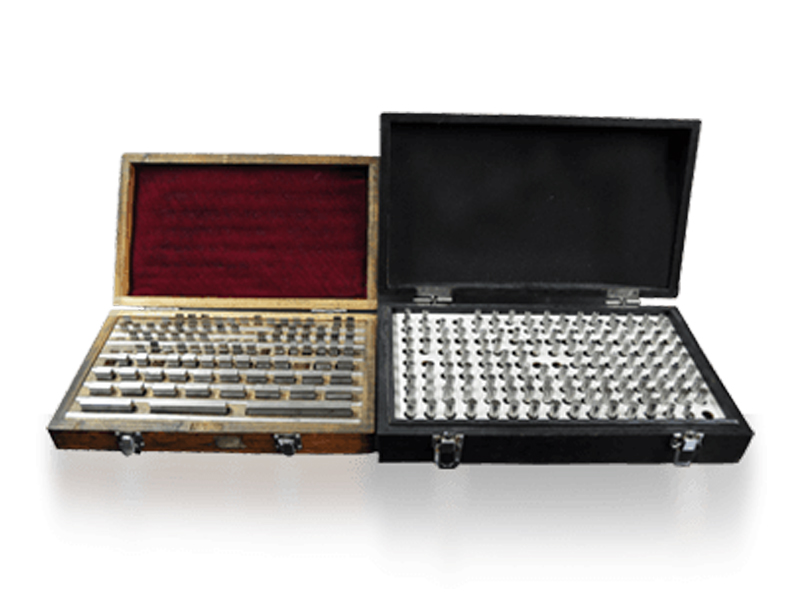

Kun Feng is equipped with advanced quality inspection instruments to ensure every manufactured part meets tight tolerances and high standards. Our QC department utilizes state-of-the-art measurement tools to validate dimensional accuracy, material properties, and overall consistency.

Action

We take immediate and effective corrective actions whenever deviations or quality issues are identified. More than just solving problems, our approach focuses on root cause analysis, cross-functional collaboration, and preventive strategies to avoid recurrence. Through ongoing evaluation and optimization, we ensure that every improvement strengthens our process stability, product quality, and customer satisfaction — forming a virtuous cycle of continuous advancement.