Strengthening Japan-Taiwan Cooperation to Become Global Market Leaders

Commemorating the Taiwan Business Matching Event

Amid growing geopolitical risks and protectionist trends forcing the reorganization of global supply chains, Taiwan has been gaining prominence as a “trusted partner” backed by its comprehensive industrial clusters and robust logistics infrastructure. Beyond its global leadership in semiconductors, IC design, and electronic components, Taiwan has made significant strides into high-value industries such as precision machinery, automotive components, aerospace, medical devices, and renewable energy technologies. Ahead of the business matching event in November, let’s explore Taiwan’s strengths and the future of Japan-Taiwan collaboration.

Deepening Japan-Taiwan Collaboration Through Complementary Strengths

Japan and Taiwan have long maintained a highly complementary economic relationship. In 2024, their bilateral trade reached 72.2 billion USD, making Japan Taiwan’s third-largest trading partner and Taiwan Japan’s fourth-largest. Japan excels in semiconductor manufacturing equipment, materials, machine tools, automotive parts, and energy-related industries, while Taiwanese companies have become integral to Japanese supply chains through consistent quality management and flexibility. For example, in the automotive components sector, Japan is Taiwan’s second-largest export destination, and Taiwanese suppliers are trusted for their stable quality and reliable delivery.

For global corporations, Taiwan offers advanced technology, high-level manufacturing capabilities, and collaborative business models—all underpinned by innovation and supply chain stability. These strengths explain how Taiwan has secured its position as a major player in the ever-evolving global market.

The Strength of Taiwan’s Manufacturing: Trusted Worldwide

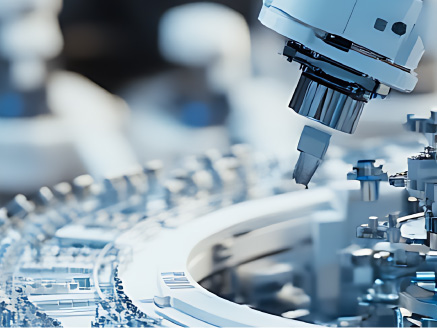

One of Taiwan’s greatest strengths in metal fabrication and precision processing lies in its flexible supply chain. With over 20,000 related enterprises nationwide, Taiwan has built a complete value chain covering everything from raw material processing to finished component production. In particular, the central and southern industrial clusters demonstrate remarkable maturity, capable of handling both mass production and small-batch, multi-variety manufacturing with agility.

Equally important is Taiwan’s success in smart manufacturing and high-value transformation. For instance, in the fastener industry, to avoid falling into low-price competition, companies have expanded into sectors such as aerospace, medical, and automotive. They have introduced defect prevention systems and optimized process management, reflecting a strategic shift toward high-value niche markets and a move from traditional mass production to intelligent, value-oriented manufacturing.

Furthermore, Taiwan has strengthened its global competitiveness through digital transformation (DX) and ESG initiatives. Automated production management has improved yield rates, while the nation leads in green manufacturing—achieving carbon reduction, higher resource efficiency, and sustainable industrial operations.

Expanding Applications Through Advanced Precision Processing

Taiwan’s precision processing technologies are widely applied across automotive, electronics, machinery, machine tools, and semiconductor equipment industries. In the automotive sector, Taiwan supplies engines, transmissions, and chassis components, with many manufacturers certified under the international IATF 16949 standard. In electronics, it provides precision metal casings, heat dissipation modules, and connectors for notebook PCs and smartphones. In the machine tool sector, Taiwan supplies major module components such as spindles, turrets, and linear guides to global manufacturers. Meanwhile, in the semiconductor field, high-precision parts such as vacuum chambers and wafer carriers are produced in cleanroom environments.

These diverse applications exemplify the flexibility and high-precision machining capabilities that underpin Taiwan’s industrial competitiveness.

Creating New Synergies Through a Large-Scale Business Matching Event

From November 10 to 14, 2025, approximately 100 Taiwanese companies will participate in a business matching event across three Japanese cities—Tokyo, Osaka, and Fukuoka. This event provides a direct platform for Japanese trading houses and manufacturers to meet Taiwanese suppliers in fields such as metalworking, sheet metal, non-metal processing, precision components, machine tools, and hand tools.

Each city has its own industrial characteristics: Tokyo is a hub for trading and precision manufacturing headquarters, Osaka is the center of manufacturing and trade in western Japan, and Fukuoka hosts clusters for semiconductors and automotive industries. By connecting Taiwan’s strengths with regional industrial needs, the event aims to create concrete business opportunities.

Since 2022, more than 600 Japanese companies have participated, resulting in around 1,500 business meetings. Major participants have included Mitsubishi Group, Denso, Toyota Group affiliates, and leading tool manufacturers, all achieving tangible results.

Japan, as one of the world’s top manufacturing nations, holds particularly high standards for quality. This in-person event offers an excellent opportunity not only to understand Taiwan’s product competitiveness and technical advantages but also to grasp the full capability of Taiwan’s manufacturing industry and lay the groundwork for long-term partnerships.

Looking Ahead: Strengthening Future Japan-Taiwan Relations

In the coming years, Japan-Taiwan cooperation is expected to grow stronger in fields such as semiconductors, new energy vehicles, and advanced electronics. Combining Japan’s cutting-edge R&D capabilities with Taiwan’s precision manufacturing and flexible production capacity will further enhance international competitiveness.

Taiwan is no longer viewed merely as the “world’s factory” but as a “global partner.” Through deeper collaboration with Japanese enterprises, Taiwan’s industrial structure is evolving toward higher sophistication. The complementary strengths of both nations will continue to drive sustainable and strategic growth.

As global trade faces increasing uncertainty and supply chain disruptions, industries worldwide must enhance adaptability and resilience across regions. Japan’s manufacturing sector and Taiwan’s precision component industry have long maintained a positive relationship. Accelerating technological innovation, integrating supply chains, and developing emerging industries will further strengthen their mutual competitiveness and contribute to stable, long-term growth.

With Taiwan’s world-class production capacity and Japan’s forefront innovation, this business matching event marks a new milestone in bilateral cooperation. It is expected to deepen Japan-Taiwan relations and elevate both countries’ global standing in high-value manufacturing.

Event Details

The “Taiwan Precision Parts Procurement Meeting” will feature manufacturers and traders of precision, industrial, and mechanical components, while the “Taiwan High-End Metal Products and Hand Tools Procurement Meeting” will showcase companies specializing in precision hardware, professional hand tools, premium fasteners, and mold-related products. Admission is free, attendees can enter and leave freely, and Japanese interpreters will be available. For more details, please visit the respective venue pages.

- Fukuoka Venue: November 10 (Mon), 10:00–16:00, Grand Hyatt Fukuoka

- Osaka Venue: November 12 (Wed), 10:00–17:00, Swissôtel Nankai Osaka

- Tokyo Venue: November 14 (Fri), 10:00–16:30, Keio Plaza Hotel Shinjuku

Ad by The International Trade Administration, Ministry of Economic Affairs