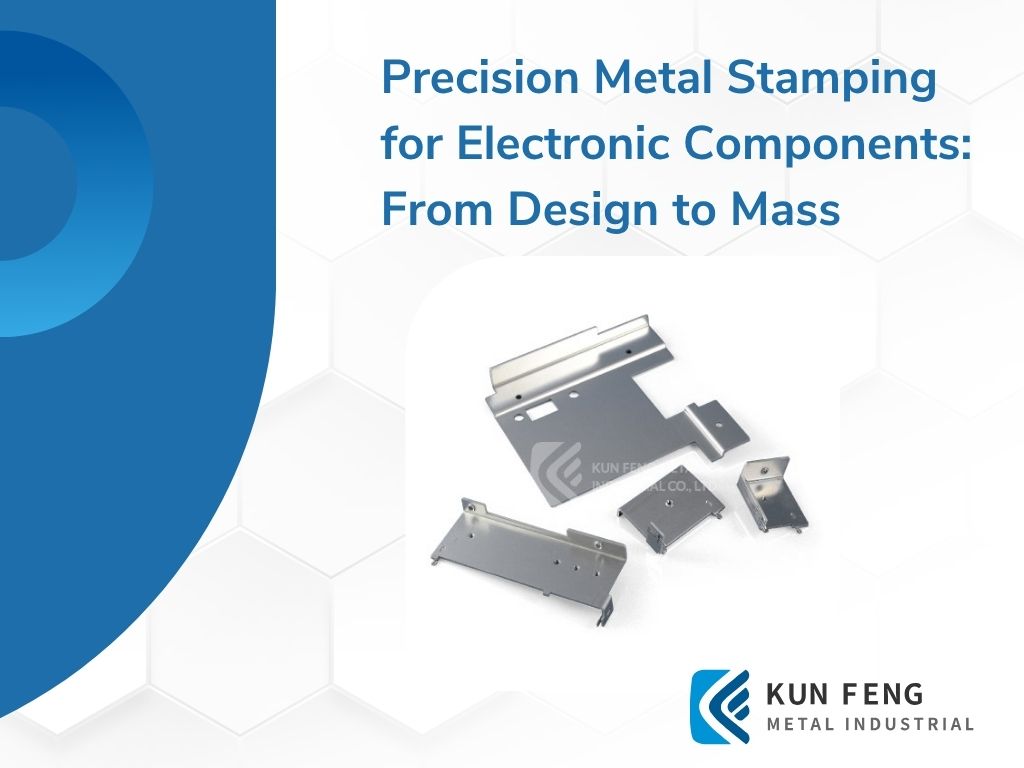

Precision Metal Stamping for Electronic Components: From Design to Mass

In today’s electronics industry, where miniaturization and precision define competitiveness, metal stamping plays a crucial role in the production of high-performance electronic components. From micro-connectors and terminals to shielding parts and brackets, stamped metal pieces form the backbone of many electrical systems used in consumer electronics, automotive modules, and industrial devices.

At Kun Feng, we combine advanced stamping technology with decades of manufacturing experience to produce high-precision metal parts that meet the demanding requirements of global electronics manufacturers.

1. The Role of Metal Stamping in Electronics Manufacturing

Metal stamping has become indispensable in modern electronics manufacturing. It enables the production of small, intricate parts with tight tolerances at high speed and low cost. Compared to machining or casting, stamping provides exceptional repeatability and dimensional control.

Typical stamped electronic components include:

-

Connectors and contact terminals for stable electrical transmission

-

EMI/RFI shielding covers that protect circuits from electromagnetic interference

-

Battery plates, clips, and holders for secure power connections

-

Grounding springs and heat-dissipation fins for better reliability

-

Mounting plates and brackets used in electronic housings

Each of these components directly influences the electrical performance, safety, and lifespan of the final product.

2. From Tooling Design to Production Efficiency

Every successful stamping project starts with a precision-designed die. At Kun Feng, our in-house tooling team designs and builds high-precision stamping dies that ensure stable production and consistent quality with minimal material waste.

After validation, the die is transferred to our stamping line for mass production, ensuring repeatable performance and stable output across every batch.

Our process includes:

-

Material selection: choosing metals like copper, brass, stainless steel, or aluminum for optimal conductivity and corrosion resistance.

-

Precision stamping: controlling dimensional tolerances to ensure compatibility with PCB assemblies or housing units.

-

Surface finishing: applying plating, coating, or deburring to improve contact performance and durability.

This integrated workflow ensures that Kun Feng delivers reliable, cost-efficient, and repeatable stamping solutions for the electronics industry.

3. Comprehensive Quality Control for Reliable Results

Kun Feng enforces strict quality management throughout every stage of production — from product development and manufacturing to final inspection. Each process is carefully monitored to ensure compliance with customer specifications and international standards such as ISO 9001 and RoHS. In addition, continuous staff training and process evaluation are implemented to maintain product reliability, consistency, and quality performance.

4. Supporting OEM/ODM Production Needs

As a professional OEM/ODM stamping manufacturer, Kun Feng provides flexible cooperation models to fit customer requirements—from initial prototyping to full-scale production.

Our engineering team assists clients in:

-

Optimizing product design for manufacturability

-

Reducing tooling costs through intelligent die layouts

-

Managing large-scale production with strict timeline control

-

Customizing surface treatments and packaging for final assembly

Whether it’s a small batch of precision clips or high-volume production of connector terminals, we ensure efficiency, precision, and consistency at every step.

5. Why Choose Kun Feng for Your Electronic Stamping Projects

With over 30 years of experience, Kun Feng has developed a complete manufacturing system that combines advanced technology with meticulous craftsmanship.

Our strengths include:

-

Professional tooling design and development ensure stable and reliable stamping performance over time.

-

Stable mass production with consistent dimensional precision

-

Multi-stage quality inspection and traceability

-

Environmentally responsible manufacturing aligned with ISO standards

-

Global OEM/ODM support and export-ready logistics

From raw material sourcing to final packaging, Kun Feng guarantees precision, performance, and partnership for your electronic stamping needs.

Frequently Asked Questions (FAQ)

Q1: What types of electronic components can be made with metal stamping?

A1: Metal stamping is ideal for producing electronic connectors, shielding cases, terminals, battery contacts, clips, brackets, and small mechanical fittings used in circuit boards, sensors, and control units.

Q2: What materials does Kun Feng commonly use for stamped electronics?

A2: We work with a wide range of metals including copper, brass, stainless steel, aluminum, and nickel-plated steel. Material selection depends on conductivity, strength, corrosion resistance, and cost requirements.

Q3: Can Kun Feng handle customized stamping designs?

A3: Yes. Kun Feng provides full OEM/ODM customization, including tooling development, prototyping, and surface finishing. Clients can submit drawings or samples, and our engineering team will provide a complete stamping solution.

Q4: How does Kun Feng ensure quality consistency in mass production?

A4: Quality is controlled at every stage—from die design to final inspection—supported by systematic process monitoring and internal quality audits.

Q5: What industries use stamped electronic parts from Kun Feng?

A5: Our stamped parts are widely applied in automotive electronics, consumer devices, industrial controls, and communication systems, supporting both domestic and global clients.

Conclusion

As electronic products continue to advance toward greater functionality and compactness, the demand for precision-stamped components grows stronger. Kun Feng remains committed to delivering high-precision metal stamping solutions for electronics, ensuring every part contributes to performance, reliability, and value.

Ready to Partner with Kun Feng?

Looking for a trusted stamping manufacturer for your next electronics project?

Contact Kun Feng today to discuss your OEM/ODM requirements or request a custom quotation.

Our team is ready to provide efficient, precise, and cost-effective stamping solutions tailored to your needs.